TECHNICAL

Technical Digest

Analysis of abnormal quality lamp in an application

Abnormal phenomenon:

1. Cracking of the lamp (the position of the molybdenum chip at ends of the UV lamp is cracked, causing shutdown)

2. Blackening and deformation (the blackening and deformation of the UV lamp results in insufficient energy)

3. Uneven energy (the energy difference between the two ends of the UV lamp exceeds requirement)

4. Decay too fast (UV lamp energy decays too fast)

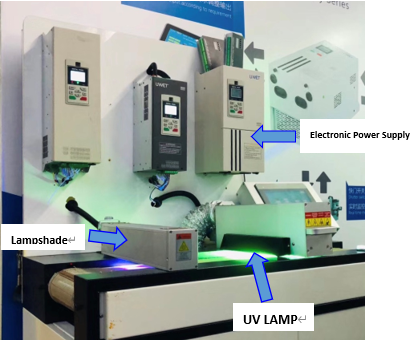

UV lamp is the most vulnerable part of the entire curing system

1.Cracking of the lamp --- molybdenum sheet is crecked

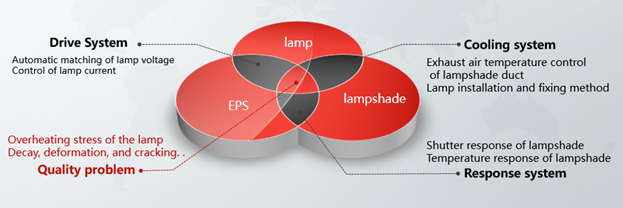

Quartz cracking must be caused by stress. There are several aspects of stress generation:

- The opening and closing of the shutter causes the vibration of the lampshade to be transmitted to the high-temperature lamp indirectly.

------ Reduce shutter cylinder pressure to mitigate vibration

- The lamp head porcelain is too tightly installed. After the thermal expansion, it shrinks with the fixed inner circle, which results in a smaller fit gap. Then the quartz thermal expansion and contraction will jam the head and the fixture on the lampshade, resulting in stress

------- Adjust the fixed gap between the lamp porcelain and the lampshade

- Overheating of the electrode part of the lamp's molybdenum sheet results in stress (the solution is to adjust the ventilation or improve the heat conduction of the lamp.)

------- Adjust the exhaust air or improve the heat conduction of the lamp

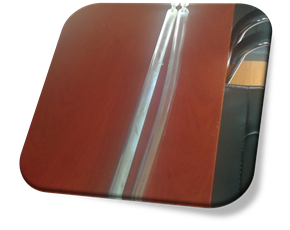

2.The blackening and deformation of lamp

The blackening and deformation of the quartz is generally caused by excessive temperature. Generally, it will be improved from the following aspects:

- The exhaust ventilation cooling system matching the lamp is not well, which leads to insufficient exhaust ventilation of the lamp, which causes the lamp to become dark and deformed for a long time.

(The solution is to adjust the exhaust air to improve)

- After the shutter is closed, the lamp continues to run for a long time at full power, which causes the lamp to become black and deformed after it is overheated.(The solution is to adjust the time for the lamp to switch to standby power after the shutter is closed)

- Improve lamp technology manufacture

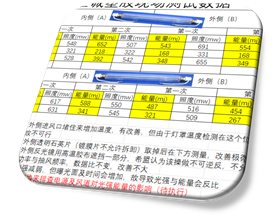

3. Uneven energy

The uneven energy at the ends of UV lamps will generally be improved from the following aspects:

1. The unreasonable way of the cooling, which causes a large temperature difference between the two ends of the lamp, which is reflected in the intensity of the lamp. (Field example: The cracked end of the lamp is concentrated on the inside, and the energy on the inside is high, which can indirectly reflect the high temperature on the inside------ Improve the way of the exhaust

2. Self-adjusting driving characteristics of the electronic power supply to ensure that there is no excessive difference in the driving temperature of the two ends of the lamp------ UWET EPS comes with this function.

3. Improve lamp technology manufacture

4.Decay too fast

The fast decay of UV lamp energy will generally be improved from the following aspects:

1. Reasonably control the temperature distribution of each position of the lamp------ Improve the way of the cooling

2. Inadequate design space

For example, the lamp's power density is too high, which causes the lamp's temperature to be high

3. Improve lamp technology manufacture

HEAD OFFICE IN SHENZHEN:

Phone:86-755-26162525 / 2018182

Fax:86-755-26162525-807

Add:2nd Floor, Building B, YongXing Industial Park,

DaLang Street, LongHua District, ShenZhen City, GuangDong Province, China.

BUSINESS CONTACT PERSON:

Rachel

Mobile/Whatsapp: +86 18128026551

Wechat: +86 18128026551

E-mail: rachel@uwete.com

KUNSHAN OFFICE:

Mod:+86 18138849379

Add:Room1101, Building 22, Huangpu City Garden,

Development District, Kunshan, Suzhou City,

Jiangsu Province, China.

Shenzhen UWET Electric Technologies Co., Ltd. 粤ICP备17012322号 Powered by:300.cn